Double Layer Glass Reactor

1.Description:1L- 200L chemical Lab Equipment Double Layer Glass Reactor

2.Volume:1L 2L 5L 10L 20L 30L 50L 80L 100L 150L 200L

3.Reacting temperature: - 80~300℃

4.GG17, SS,PTFE sealing

5.University brands designated

6.Explosion-prood device is optional for glass reactors above 5L jacketed glass reactors

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

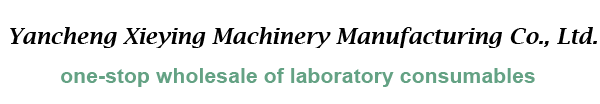

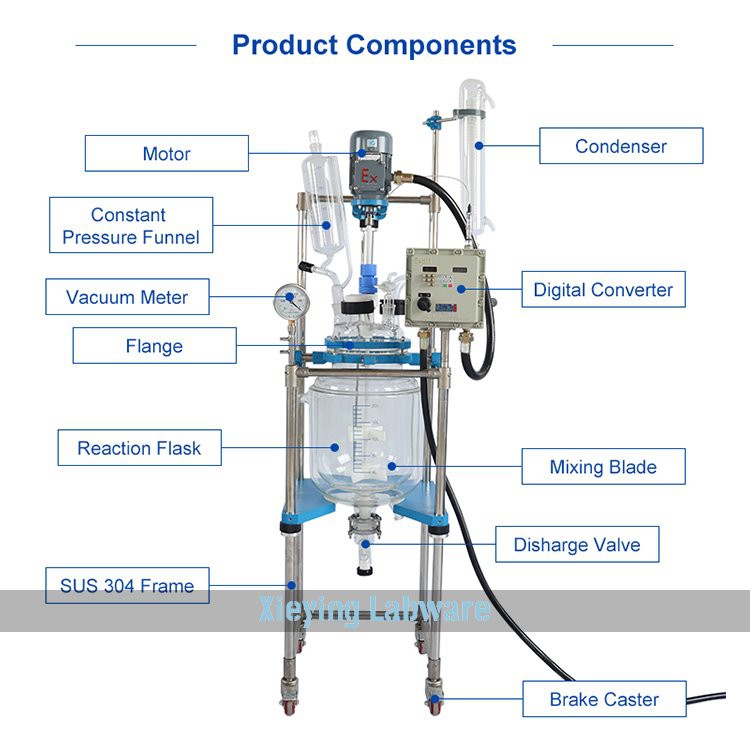

Product Introduction

Double Layer Glass Reactor:

1. Description:1L- 200L chemical Lab Equipment Double Layer Glass Reactor

2. Volume:1L 2L 5L 10L 20L 30L 50L 80L 100L 150L 200L

3. Reacting temperature: - 80~300℃

4. GG17, SS,PTFE sealing

5. University brands designated

6. Explosion-prood device is optional for glass reactors above 5L jacketed glass reactors

7. Ac motor,brushless,no sparkle

8. Constant rotationg speed

9. Reflow and distillation system

10. Chemical laboratory use

11. Reaction mixing vessel

About Double Layer Glass Reactor:

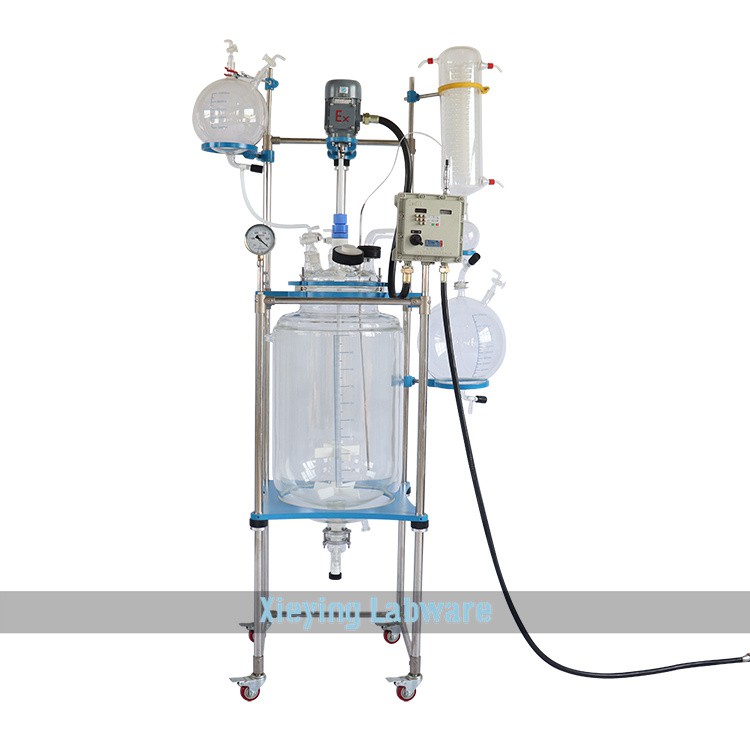

Double Layer glass reactor is mainly applied in Bio-chemical, Pharmaceutical & Fine-Chemical Trades. It can be jointed with vacuum pump, chilling circulator , heating circulator is widely used in the process like Combination, Reaction, Separation,Concentration, etc It is adopted in the industry of chemical products, advanced material synthesis experiment, etc.

Features of Double Layer Glass Reactor:

- High quality Borosilicate Glass 3.3 with excellent physical and chemical properties

- Rugged steel-reinforced PTFE stirrer with anchor agitator which is suitable for a wide range of material viscosity.

- Frequency-conversion stirring system + PTFE seal & bearing system

- Digital display and control

- Easy-to-install modular design for exceptional ease and low cost of maintenance

- High quality SUS304 frame

Working Principle of Double Layer Glass Reactor:

Under the vacuum negative pressure condition, the stirring rod is stirred at a constant speed by using the speed-regulating knob, so that the material is fully reacted in the kettle body, and the heating or cooling reaction of the material in the kettle is indirectly heated by the glass interlayer external heating or cooling device, and the reaction process is heated during the heating process. The resulting solvent vapor is rapidly cooled, distilled or refluxed via a cooling coil of a glass condenser. After the reaction is completed, the material can be quickly discharged through the oblique discharge valve.

Parameters of Double Layer Glass Reactor:

| Model | JR-1L | JR-2L | JR-5L | JR-10L | JR-20L | JR-30L |

| Electrical Requirements | 110/220V, 60Hz 1 PH | 110/220V, 50/60Hz 1 PH | ||||

| Standard Stirring Motor Power | 120W | |||||

| Reaction Vessel Capacity | 1L | 2L | 5L | 10L | 20L | 30L |

| Cooling/Heating Capacity | 1L | 1.5L | 2L | 3L | 6L | 10L |

| Glass Vessel Temperature Range | -120℃∽250℃ | |||||

| Inner Vessel Pressure | Under 0.098Mpa | |||||

| Installation Dimension (WD-H mm) | 440*360 *1325 | 440*360*1325 | 520*500*1510 | 700*600*2030 | 720*650*2110 | 750*650*2450 |

| Weight(kg) | 40 | 40 | 60 | 90 | 110 | 10L |

| Model | JR-50L | JR-80L | JR-100L | JR-150L | JR-200L |

| Electrical Requirements | 110/220V, 60Hz 1 PH | 110/220V, 50/60HZ 1 PH | |||

| Standard Stirring Motor Power | 120W | 200W | 750W | ||

| Reaction Vessel Capacity | 50L | 80L | 100L | 150L | 200L |

| Cooling/Heating Capacity | 16L | 24L | 30L | 35L | 40L |

| Glass Vessel Temperature Range | -120°C∽250°C | ||||

| Inner Vessel Pressure | Under 0.098Mpa | ||||

| Installation Dimension (WD-H mm) | 750*650*2450 | 850*700*2550 | 850*700*2550 | 1000*1300*3000 | 1000*1300 *3200 |

| Weight(kg) | 120 | 140 | 160 | 210 | 270 |

Hot Tags: double layer glass reactor, China, suppliers, manufacturers, factory, custom, wholesale, price, free sample, made in China

No Information